When it comes to roofing systems, underlayment plays a crucial role in protecting homes from the elements. Synthetic roof underlayment has gained popularity in recent years due to its superior performance compared to traditional felt materials. In this article, we will explore the various materials used in synthetic roof underlayment, their advantages, and how they contribute to a more resilient roofing system.

What is Synthetic Roof Underlayment?

Synthetic roof underlayment is a modern alternative to traditional felt underlayment, made from advanced polymers and engineered materials. Unlike felt, which is primarily made from asphalt-saturated paper, synthetic underlayment is designed to provide enhanced durability, moisture resistance, and overall performance.

Key Materials Used in Synthetic Roof Underlayment

- Polypropylene

Overview: Polypropylene is one of the most common materials used in synthetic roof underlayment. This thermoplastic polymer is lightweight, durable, and resistant to moisture, making it an excellent choice for roofing applications.

Advantages:

- Moisture Resistance: Polypropylene does not absorb water, preventing issues like mold growth and degradation that can occur with traditional felt.

- UV Stability: This material is resistant to UV radiation, helping to maintain its integrity and performance over time.

- Durability: Polypropylene is highly resistant to tears and punctures, providing reliable protection during installation and throughout the life of the roof.

- Polyethylene

Overview: Another key material in synthetic roof underlayment is polyethylene, a versatile plastic known for its strength and durability. High-density polyethylene (HDPE) is often used in roofing applications due to its robust properties.

Advantages:

- Waterproofing: Polyethylene is inherently waterproof, providing a reliable barrier against moisture infiltration.

- Tear Resistance: HDPE is significantly tougher than traditional felt, reducing the risk of rips and tears during installation or due to weather-related stresses.

- Lightweight: This material is lightweight, making it easier to handle and install compared to heavier alternatives.

- Thermoplastic Olefin (TPO)

Overview: Thermoplastic olefin (TPO) is a roofing membrane material that has found its way into synthetic underlayment products. TPO combines polypropylene and ethylene-propylene rubber to create a flexible, durable underlayment option.

Advantages:

- Energy Efficiency: TPO materials often have reflective properties, helping to reduce heat absorption and improve energy efficiency in buildings.

- Weather Resistance: TPO is resistant to a wide range of weather conditions, including high winds, rain, and temperature fluctuations, ensuring long-lasting performance.

- Flexibility: The flexibility of TPO allows for easy installation and adaptation to different roofing shapes and structures.

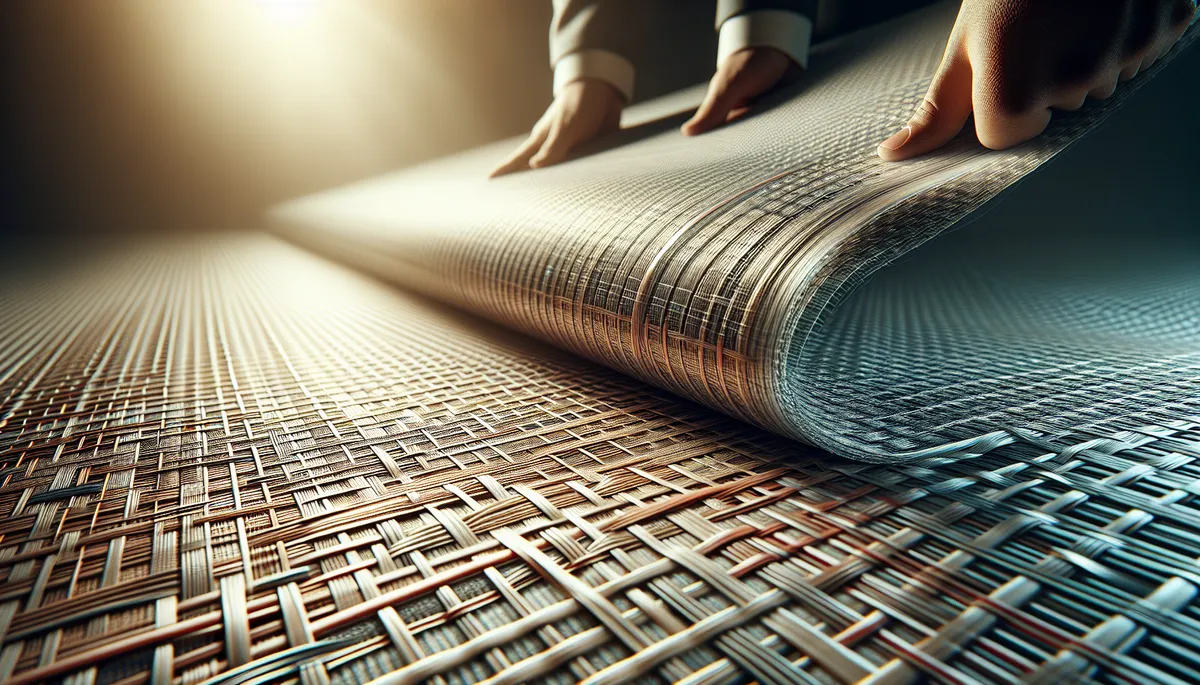

- Reinforced Fibers

Overview: Many synthetic roof underlayments incorporate reinforced fibers, such as polyester or fiberglass, to enhance strength and durability.

Advantages:

- Increased Strength: Reinforced fibers improve the tensile strength of the underlayment, making it more resistant to tearing and puncturing during installation and service life.

- Dimensional Stability: The addition of fibers helps maintain the shape and structure of the underlayment, preventing sagging or deformation over time.

- Adhesive Backing

Overview: Some synthetic underlayment products feature an adhesive backing that allows for easy installation and secure attachment to the roof deck.

Advantages:

- Quick Installation: Adhesive backing can simplify the installation process, reducing labor time and effort.

- Secure Bond: The adhesive creates a strong bond with the roof deck, minimizing the risk of movement or displacement during installation or high winds.

Advantages of Synthetic Roof Underlayment Over Traditional Materials

- Superior Moisture Management

Synthetic underlayment excels in moisture management, offering waterproof barriers that outperform traditional felt materials. The lack of water absorption in synthetic options prevents mold growth and protects the roof deck from water damage. - Enhanced Durability and Longevity

The combination of advanced materials and reinforced fibers in synthetic underlayment makes it more durable than traditional felt. Synthetic options resist tearing, puncturing, and degradation, leading to a longer lifespan and reduced need for maintenance. - UV Resistance

Synthetic underlayment is often designed to withstand prolonged exposure to UV radiation, while traditional felt can deteriorate and lose effectiveness when exposed to sunlight. This UV resistance helps maintain the integrity of the roofing system over time. - Lightweight and Easy to Handle

Synthetic roof underlayment is typically lighter than traditional felt, making it easier for contractors to handle and install. This lightweight nature can speed up the installation process, leading to time and labor cost savings. - Adaptability

Synthetic materials can be manufactured to meet specific performance needs, making them highly adaptable for various roofing applications and environmental conditions. - Reflective Properties

Certain synthetic underlayment options feature reflective properties that can help improve energy efficiency by reducing heat absorption, contributing to cooler indoor temperatures and lower energy costs.

There are many more benefits to synthetic roofing underlayment.

Conclusion

Synthetic roof underlayment represents a significant advancement in roofing technology, offering homeowners and contractors a more effective solution than traditional felt materials. With a variety of high-performance materials such as polypropylene, polyethylene, TPO, and reinforced fibers, synthetic underlayment delivers superior moisture management, durability, and ease of installation.

As the roofing industry continues to evolve, understanding the materials used in synthetic underlayment is essential for making informed choices that enhance the longevity and performance of roofing systems. By opting for synthetic roof underlayment, homeowners can enjoy peace of mind knowing they have made a smart investment in their home’s protection and energy efficiency. If you offer this product and want sales representation for your building materials please reach out

Related Resources

Frequently Asked Questions

What materials are used in synthetic roof underlayment?

Synthetic roof underlayment is primarily made from polypropylene or polyethylene polymers that are woven or spun into a fabric-like sheet. These base polymers are often reinforced with fiberglass scrim or additional polymer layers, then treated with UV inhibitors, anti-slip coatings, and water-resistant additives. The multilayer construction provides strength, flexibility, and weather resistance.

How is synthetic underlayment different from felt paper?

Unlike traditional felt paper which uses asphalt-saturated organic materials, synthetic underlayment uses engineered polymers like polypropylene or polyethylene. This makes it lighter, stronger, more tear-resistant, and better able to withstand UV exposure. Synthetic materials don’t absorb water, dry faster, and maintain consistent performance across temperature ranges where felt can become brittle or deteriorate.

What makes synthetic underlayment more durable?

The durability of synthetic underlayment comes from its polymer-based construction, which resists tearing, puncturing, and UV degradation far better than organic felt. Many products include fiberglass reinforcement for added strength, and polymer chemistry allows for consistent performance without breaking down from moisture exposure. Anti-slip coatings and UV stabilizers further enhance longevity and safety.

Are all synthetic roof underlayments the same?

No, synthetic underlayments vary significantly in quality and composition. Differences include the type of base polymer (polypropylene vs polyethylene), whether they’re woven or non-woven, the presence and type of reinforcement layers, UV resistance ratings, slip resistance, and water permeability. Premium products typically use multi-layer construction with superior additives for enhanced performance and longer warranties.